Powder Coating

Powder Coating

Paradigm Manufacturing offers full powder coating services, a great compliment to our painting services, providing a quality finish.

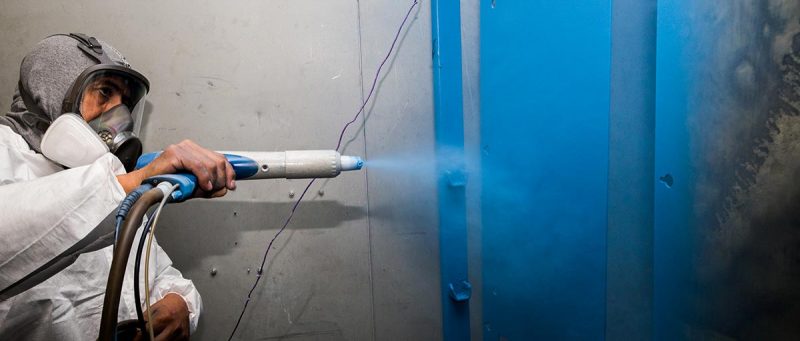

Power Coating is the process of using very fine, dry particles of resin with a variety of pigment colors, to paint products. The resin powder is applied with an electrostatically-charged spray gun that allows the resin powder to “stick”.

This process starts with a thorough cleaning process. This first step in the process is the key to a successful final product. Cleaning is done by blasting, sanding and washing parts in an industrial washer that combines heat and high pressure to remove any unwanted particles.

Once the product is cleaned, it is then painted, and placed in special industrial-sized ovens that allow the powder resin to melt and fuse to the metal. This creates a uniform, thick and durable finish.

Powder coating is available in a variety of colors, glosses and textures. This process is resistant to chemicals, UV Rays and cracking or chipping, and is excellent for any project.

Paradigm Manufacturing offers full powder coating services, a great compliment to our painting services, providing a quality finish.

The powder coating process uses very fine, dry particles of resin with the pigment color of your choice. The resin powder is applied with an electrostatically-charged spray gun, similar in concept to applying solvent-based paint.

When the resin powder is sprayed onto metal, it sticks because it’s grounded, attracting charged resin powder like a magnet. The charged powder adheres to the metal and is then melted by baking at 380 degrees Fahrenheit in special industrial-sized ovens. The melted resin fuses to the metal, providing a uniform, thick and durable finish.

The result is a strong durable finish that is resistant to chemicals, wear, and chipping.